Hardware PWM Signal Output

Overview

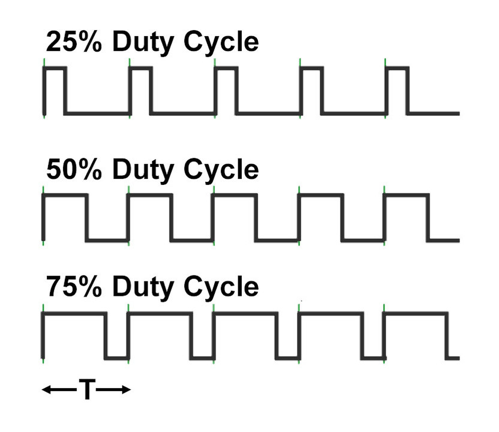

Generates PWM (Pulse Width Modulation) output with configurable frequency (Hz) and duty cycle (%). Can be used for various purposes including LED brightness control, servo motors, DC motor control, etc. Outputs hardware PWM signals using dedicated PWM pins.

Supported GPIO

- Raspberry Pi 0~4

- Raspberry Pi 5

- BeagleBone Black/Green

- Jetson Nano

Maximum output frequency for each hardware platform:

– Raspberry Pi 0~4: 30 MHz

– Raspberry Pi 5: 25 MHz

– BeagleBone Black/Green: 400 MHz

– Jetson Nano: 25 MHz

– Raspberry Pi 0~4: 30 MHz

– Raspberry Pi 5: 25 MHz

– BeagleBone Black/Green: 400 MHz

– Jetson Nano: 25 MHz

Commands

[INIT]

Configures initial PWM settings.

| Item | Type | Description |

|---|---|---|

| PWM Pin | WRITE | Selects the pin to output PWM signals. |

| Frequency (Hz) | WRITE | Sets the output frequency. |

[SET_DUTY_CYCLE]

Outputs PWM signal with the specified duty cycle.

| Item | Type | Description |

|---|---|---|

| Duty Cycle (%) | WRITE | Outputs PWM signal with the specified duty cycle (0~100%). |

Example

Objective

Control the brightness of a red LED by adjusting the PWM signal duty cycle from 0-100% using a dashboard slider widget.

Parts

| Part | Quantity |

|---|---|

| Raspberry Pi 4 * | 1 |

| Red LED | 1 |

| 220Ω Resistor ** | 1 |

* Other compatible hardware may be used. See Supported GPIO for details.

** For resistor value selection method, refer to here.

** For resistor value selection method, refer to here.

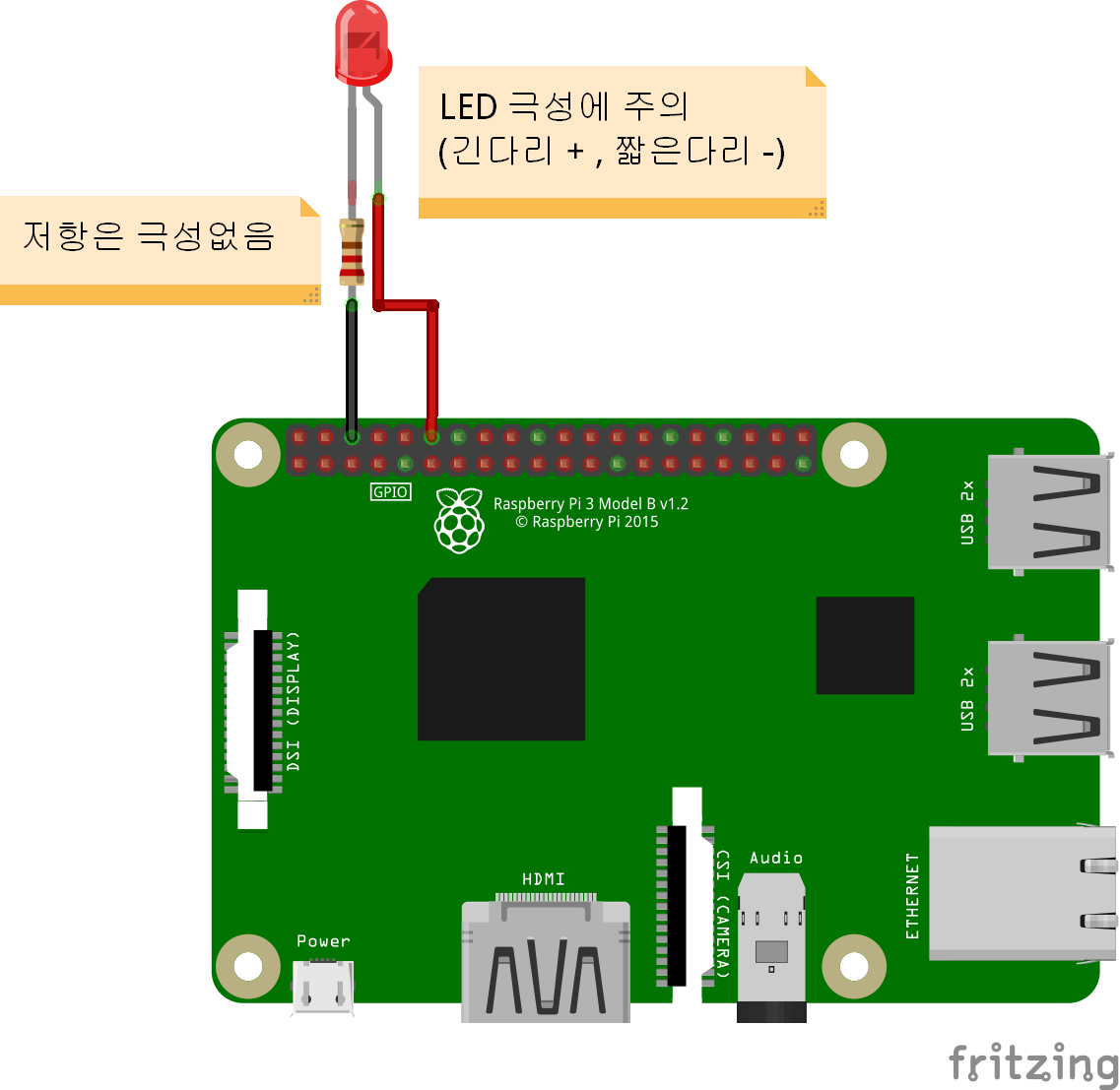

Wiring

Connect each component to the corresponding connection as listed in each row below.

| Component 1 | Component 2 | GPIO |

|---|---|---|

| LED + Pin | | 18 |

| LED – Pin | 220Ω Resistor | GND |