Servo Motor Control

Overview

A library for controlling the position or speed of servo motors. Primarily used for steering in radio-controlled model cars and aircraft, also known as RC servo motors.

This is a different type of motor from industrial servo motors used in factory automation.

Compatible Modules

All RC servo motors including SG90, MG90S, MG996R, etc.

Supported GPIO

- Raspberry Pi 0~4

- Raspberry Pi 5

- BeagleBone Black/Green

- Jetson Nano

Commands

[INIT]

Configures initial settings for the servo motor.

| Item | Type | Description |

|---|---|---|

| GPIO Pin or PWM Selection * | WRITE | Enter the GPIO pin number connected to the servo motor’s SIGNAL wire (orange or yellow) or select a PWM pin. |

| Type | WRITE | Select servo motor type (Positional Rotation, Continuous Rotation). |

* Raspberry Pi 0~4: Enter GPIO number directly (all GPIO pins available)

Raspberry Pi 5, BeagleBone Black/Green, Jetson Nano: Select one of the PWM pins shown in the combo box.

Raspberry Pi 5, BeagleBone Black/Green, Jetson Nano: Select one of the PWM pins shown in the combo box.

Type: Positional Rotation

| Item | Type | Description |

|---|---|---|

| Min Position Pulse Width(ms) * | WRITE | Enter the input pulse width when the servo motor is at minimum position. |

| Max Position Pulse Width(ms) * | WRITE | Enter the input pulse width when the servo motor is at maximum position. |

| Min Position(º) | WRITE | Enter the servo motor’s minimum position in degrees (e.g., 0º). |

| Max Position(º) | WRITE | Enter the servo motor’s maximum position in degrees (e.g., 180º). |

Type: Continuous Rotation

| Item | Type | Description |

|---|---|---|

| Min Speed Pulse Width(ms) * | WRITE | Enter the input pulse width when the servo motor is at minimum speed. |

| Max Speed Pulse Width(ms) * | WRITE | Enter the input pulse width when the servo motor is at maximum speed. |

| Min Speed(%) | WRITE | Enter the servo motor’s minimum speed as a percentage. For reverse rotation, negative values are possible (e.g., -100%). |

| Max Speed(%) | WRITE | Enter the servo motor’s maximum speed as a percentage (e.g., 100%). |

* Pulse width according to servo motor angle or speed may vary by product, but typically:

– 1ms (min position) ~ 2ms (max position) or 0.544ms (min position) ~ 2.4ms (max position)

– If the motor doesn’t rotate to the specified angle, adjust the input pulse width according to the product specifications.

– 1ms (min position) ~ 2ms (max position) or 0.544ms (min position) ~ 2.4ms (max position)

– If the motor doesn’t rotate to the specified angle, adjust the input pulse width according to the product specifications.

[SET_POS]

Sets the position or speed of the servo motor.

| Item | Type | Description |

|---|---|---|

| Position(º) | WRITE | Enter the servo motor position. Displayed when type is “Positional Rotation”. |

| Speed(%) | WRITE | Enter the servo motor speed. Displayed when type is “Continuous Rotation”. |

Example

Objective

When the user changes the dashboard slider widget value between 0-180, the servo motor rotates to the corresponding angle.

Parts

| Part | Quantity |

|---|---|

| Raspberry Pi 4 * | 1 |

| Servo Motor (SG90) | 1 |

| DC Power Supply | 1 |

* Other compatible hardware may be used. See Supported GPIO for details.

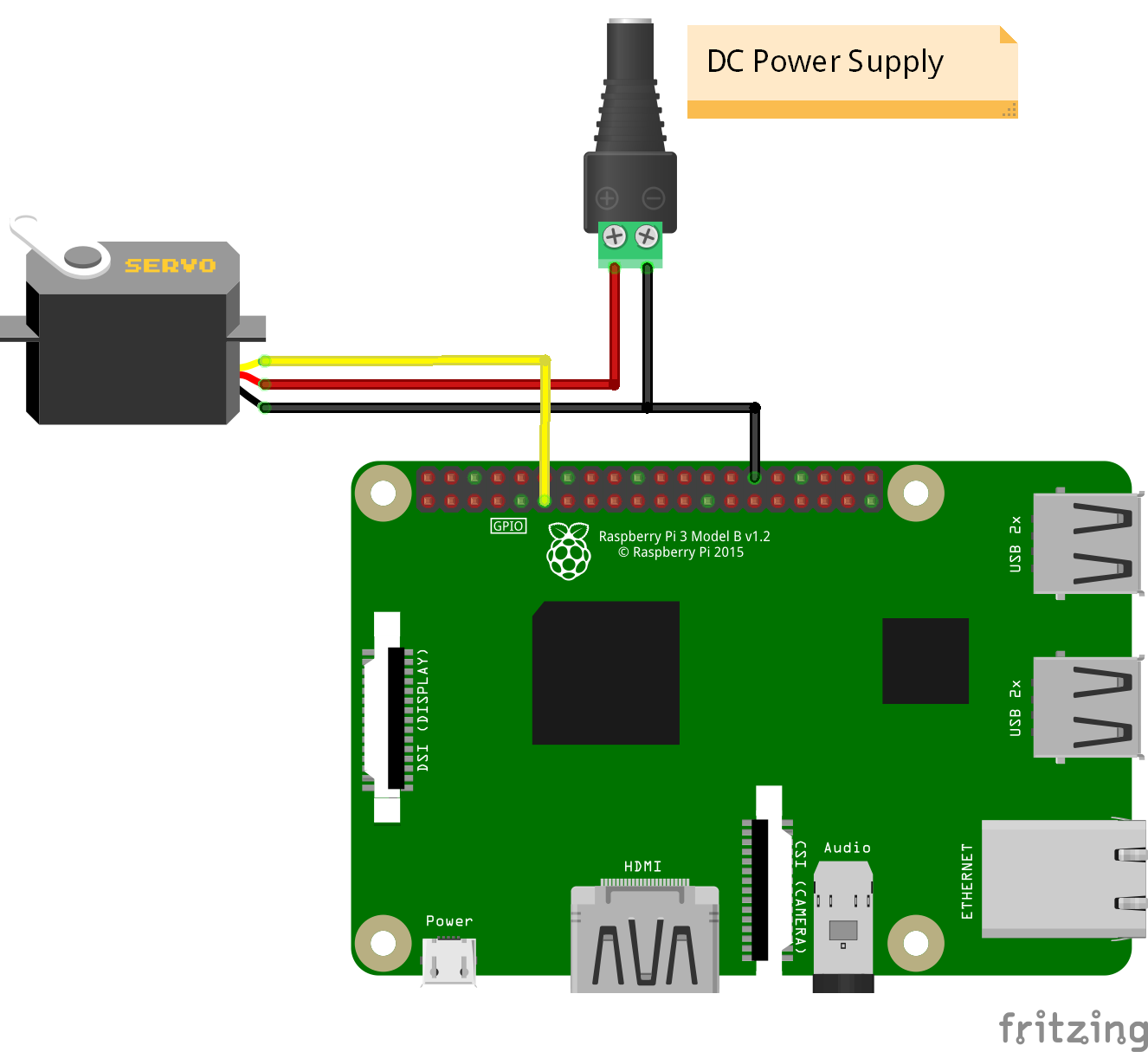

Wiring

Connect each pin to the corresponding connection as listed in each row below.

| DC Power Supply * | Servo Motor | Raspberry Pi |

|---|---|---|

| + | VIN (Red) | |

| – | GND (Black or Brown) | GND |

| | SIGNAL (Orange or Yellow) | 17 |

* Use an appropriate external DC power supply considering the servo motor’s voltage and current consumption.